double-module magnetic linear motor multifunctional pick and place machine

1.Product details

Price: $75000/unit

Customization: According to customer needs.

HT-E5D machine is Dual system,dual module multifunctional mounter with high capacity of 80000CPH. It can mount capacitors,resistors,LED3014/3020/3528/5050,IC and shaped components. It applies to power driver,electric board,lens,linear bulb,household appliance and etc.

technical parameter

| Place of origin |

Guangdong,China |

| Model number |

HT-E5D |

| dimension |

1650*2000*1550 |

| PCB size |

100*100~500*300 |

| PCB thickness |

0.5~3mm |

| components |

LED,capacitors,resistors,shaped components,etc. |

| Mounting speed |

80000CPH |

| Mounting mode |

Group picking and separate placing, separate picking and separate placing. |

| Mounting precision |

±0.02cm |

| Feeder stations |

60pcs |

| nozzles |

16pcs |

Product features

- Dual system,dual module multifunctional mounter; to produce two different product at same time.

- X、Y、Z drive way is high-end magnetic linear motor+servo motor.

- Install 4 camera and adopt vision for the flight identification.

- PCB clamping is electric clamping+adjustable pressure pneumatic

- Vision for the flight identification ,mark correction

- Electronic feeder feeding system.

- Non-stop material re-loading function.

- Auto-optimization after coordinates generated

Product parts

- Saline shaft from korea

- Mark camera from HK vision

- Grating scale from Renishaw,UK

- Guideway from IKO Japan

- Pneumatic components from SMC Japan

- Sensor from Beckhoff Germany

- Drag chain from IGUS Germany

Supply ability

80 Unit/Units per Month

Business terms

| Accepted delivery terms |

EXW, FOB, CIF, CFR |

| Accepted payment currency |

USD,CNY |

| Accepted payment type |

L/C, T/T |

| Nearest port |

Shenzhen |

Our services

- We have a professional sales manager to provide you with professional advice and services

- We provide 24-hour online service to solve your problem quickly

- We will specify the production plan for you according to your budget

- 1 year free warranty

- Visit customers regularly and gather information

- Provide latest information about technology and equipment

- Software updates are free for life

2.Company profile

Company information

| Business type |

Manufacturer,distributor/wholesales |

| Year established |

2011 |

| Country/region |

Guangdong, China |

| Total employees |

101-200 people |

| Main products |

Pick and place machine, SMT LED machine, LED light production machine, LED light assembly machine. |

| Total annual revenue |

US$1million - US$2.5million |

| Product certification |

CE ,CCC ,SIRA |

| Main markets |

Domestic market 70.00%,Southeast Asia 8.00%, South Asia 7.00% |

| ownership |

limited company |

Our certifications

The company has independently developed a number of intellectual property technologies, including 9 invention patents, 112 practical patents and 12 software Copyrights.Successively obtained“shenzhen high-tech enterprise”,“national high-tech enterprise”, “shenzhen TOP brand”, “2015 LED technology innovation award” ,“industry special contribution award” ,“the 4th China LED first innovation award” ,“industry special contribution award”, “double soft enterprise”and so on.

Our clients

the company has an absolute leading market share in the LED industry, and its products are exported to more than 20 countries including Korea, India, Vietnam, Tunisia, Egypt and Turkey.

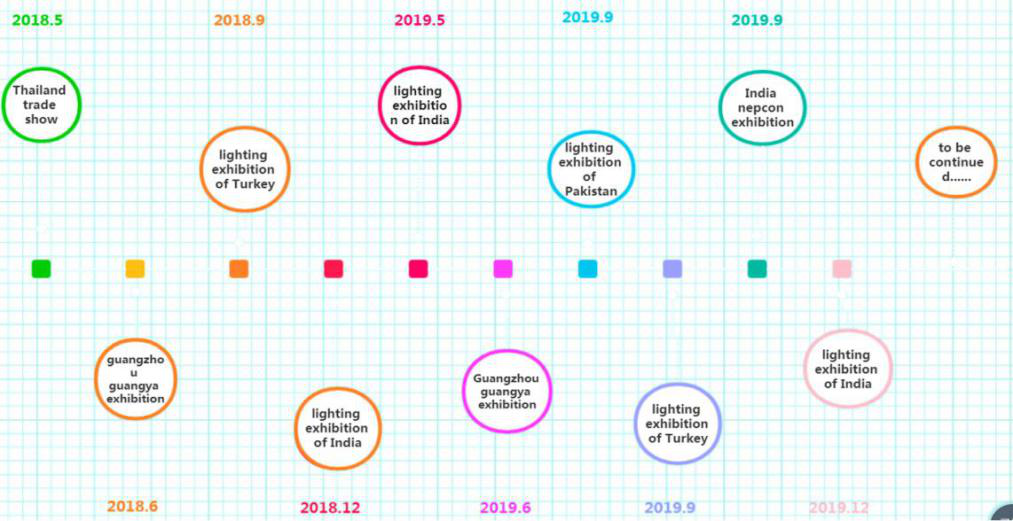

Trade shows

Since the establishment of the company, we have actively participated in relevant exhibitions held at home and abroad every year.

3.Knowledge of mounter industry

SMT Introduction

SMT patch refers to the abbreviation of a series of technological processes that are processed on a PCB basis. PCB Circuit Board is a printed circuit board.

SMT is the surface assembly technology (surface mount technology)(abbreviation of Surface Mounted Technology), is the most popular technology and process in the electronic assembly industry at present. Electronic circuit surface assembly technology (Surface Mount Technology,SMT), known as surface mount or surface mount technology. This is a kind of circuit assembly technology which installs components without pin or short lead on the surface of printed circuit board (Printed Circuit Board,PCB SMC/SMD,) or other substrate by means of reflow welding or immersion welding.

Under normal circumstances, the electronic products we use are made of electronic components, such as pcb and capacitance, resistance and so on, according to the designed circuit diagram, so all kinds of electrical appliances need different smt patch processing technology to process.

SMT basic process elements: solder paste printing -> parts mount -> reflow welding ->AOI optical inspection -> maintenance - sub-plate.

SMT process

SMT basic process elements include: screen printing (or dispensing), mount (curing), reflow welding, cleaning, testing, rework.

- Screen printing: The function is to seal the solder paste or patch glue to the PCB pad to prepare for the welding of components. Equipment used is screen printing machine (screen printing machine), located at the front end of SMT production line.

- dispensing: it is to drop the glue to the fixed position of the PCB board, and its main function is to fix the components to the PCB board. Equipment used is a dispensing machine, located at the front end of the SMT production line or behind the testing equipment.

- mount: its function is to mount the surface assembled components accurately to the fixed position of the PCB. Equipment used is a placement machine, located in the SMT production line behind the screen printing machine.

- Curing: The function is to melt the patch glue so that the surface assembled components are firmly bonded to the PCB plate. Equipment used is curing furnace, located at the back of the placement machine in the SMT production line.

- reflux welding: its function is to melt the solder paste so that the surface assembled components are firmly bonded to the PCB plate. Equipment used is reflow welding furnace, located in the back of the placement machine in the SMT production line.

- Cleaning: The function is to remove harmful welding residues such as flux from assembled PCB plates. The equipment used is a cleaning machine, the position can not be fixed, can be online or not online.

- Detection: Its function is to test the welding quality and assembly quality of the assembled PCB board. The equipment used is magnifying glass, microscope, on-line tester (ICT), flying needle tester, automatic optical detection (AOI), X-RAY detection system, functional tester, etc. position according to the need of detection, can be configured in the production line where appropriate.

- rework: its function is to detect the failure of the PCB board rework. The tools used are soldering iron, rework workstation, etc. configured in any position in the production line.

contact

Name:Brynn

Email :Brynn@eton-mounter.com

WeChat:13802252825

Telephone:138 0225 2825