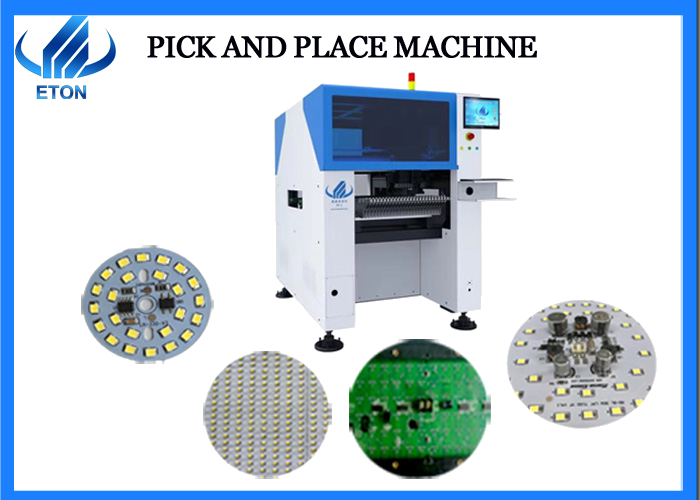

New economic middle speed multifunctional SMT machine

Product details

Modal:RT-1

Price: $33,000.00/unit

Rt-1 is a single-module multifunctional mounting machine with a capacity of 30000CPH~35000CPH. The components that can be mounted include LED3014/3020/3528/5050, capacitors, resistors, IC and special-shaped components.it applies to LED light and electric board.

technical parameter

| Place of origin |

Guangdong,China |

| Model number |

RT-1 |

| dimension |

1104*1584*1655 |

| PCB size |

50*50~400*350 |

| PCB thickness |

0.1~6mm |

| Mounting speed |

30000~35000CPH |

| Mounting mode |

Group picking and separate placing, separate picking and separate placing. |

| Mounting precision |

±0.02cm |

| Feeder stations |

32pcs |

| nozzles |

10pcs |

| Mounting height |

40mm |

| No.of camera |

2 sets of imported camera |

Product features

- X、Y、Z drive way is servo motor.

- PCB clamping is electric clamping.

- Vision for the flight identification ,mark correction.

- Electronic feeder feeding system.

- Non-stop material re-loading function.

- Auto-optimization after coordinates generated.

- Feeding way is electric feeder with double motor.

Product parts

- Saline shaft from korea

- Mark camera from HK vision

- Grating scale from Renishaw,UK

- Guideway from IKO Japan

- Pneumatic components from SMC Japan

- Sensor from Beckhoff Germany

- Drag chain from IGUS Germany

Packing & shipping

Packing details: vacuum packing and wooden case

Shipping: Shenzhen port within 30 days after payment

Port: Shenzhen

Lead time:

| Quantity (units) | Est. Time (days) |

| 1-2 | >2 |

| 30 |

To be negotiated |

Company profile

Shenzhen ETON automation equipment co., LTD., founded in 2011, is a company dedicated to SMT high-speed placement machine research and development, production, sales and after-sale technical services integrated national high and new technology, the double soft enterprise. The company always adhere to the "create national brands, to build international enterprise in China" goals, is committed to providing customers with "professional, efficient, low consumption" fully automatic SMT placement machine.ETON mission: professional, excellent technology, sharing the results.

ETON’ s purpose: to create value for customers,creating benefits for society.

ETON vision: determined to become the world’s most competitive manufacturer and service provider of pick and place machine and high-end electronic testing equipment.

Quality principle: quality first, client-oriented, continuous improvement!

Management policy: sincere business,focus on R&D,manufacturing intentions, considerate service,customer trust.

Our Certifications

The company has independently developed a number of intellectual property technologies, including 9 invention patents, 112 practical patents and 12 software Copyrights.Successively obtained "shenzhen high-tech enterprise", "national high-tech enterprise", “shenzhen TOP brand”, “2015 LED technology innovation award” ,“industry special contribution award” ,“the 4th China LED first innovation award” ,“industry special contribution award”, “double soft enterprise”and so on.

Our clients

Customer brand & Customer factory

FAQ

1) Do you have oversea after sale service?

We have set up an overseas office in India.We can offer technical support abroad. If you have any technical problem, our engineers will support you promptly.

2)How is the training?

You can send your engineers to our workshop to study, or we can send our engineers to your workshop for guidance. We guarantee that the training will not be completed until your operators are fully trained.

3) It’s hard to use the machine?

No, not at all. Touch screen display, English operation interface. Generally training about five days can be skilled in the operation of the machine.

4) Does your machines have quality certificates?

We are high-tech enterprise with CE,SIRA,CCC .

5)How about the warranty?

We guarantee it for one year free of charge. Software updates are free for life.

- Industry knowledge

SMT Placement Machine Operation Flow

1. Check before SMT placement machine starts

(1) Check air pressure, rated voltage is normal;

(2) Check the equipment for impurities, foreign bodies;

(3) Check Fida for abnormal placement;

(4) Check the suction nozzle configuration status is abnormal;

(5) Check that the safety guard is abnormal;

(6) Check whether there are unsafe safety hazards around the equipment.

2.SMT the main switch of the placement machine

(1) Turn on the voltage stabilizer switch;

(2) Turn on the air pressure switch;

(3) Rotate the main switch on the front of the equipment clockwise;

(4) According to the material configuration list, check the material tray specification, model, installation position is correct.

3. MMI initialization of SMT placement machine

Execute MMI, program to initialize automatically and check the status of each module of the device.

4.Electric power supply for SMT mounting machine

press the READY" button.

5.Carry out a regression origin action on the SMT placement machine

on the teaching box or MMI screen click Home" key to return to the origin.

6. Warmer process SMT mounting machine (Warming-Up)

In order to improve the precision of the mount, the heater is operated about 10 minutes before the start of the operation.

7.PCB file download/business confirmation

(1) open the PCB file to be done and download it;

(2) Before starting the operation, check the original operation status and confirm the production target.

8. SMT mounting machine material and component confirmation

(1) Install feeder and suction nozzle as required PCB operation;

(2) After mastering the remaining amount of the original device of the feeder, order the components that may be exhausted in advance.

9.Set up SMT placement machine transfer track and thimble (Backup Pin)

(1) Carry out transfer track width adjustment operation, set PCB fixed mode;

(2) Configure the thimble in place to support PCB underside.

10. X. Check Location and Instruction

(1) Check PCB origin;

(2) Check PCB reference mark position;

(3) (b) Examination of adsorption sites (Pickup Point);

(4) Check the stickers.

11. PCB produced SMT placement machines

12. Choose the MMI Production menu;

(1) Input production target quantity on > column of < production plan;

(2) press the "START" key of the operation panel.

13.SMT inspection items in the production of placement machines

(1) Check the surplus of components of the feeder;

(2) Check the matching of components (2 hours for cycle);

(3) Plastic belt removal and cleaning of feeder;

(4) Pickup poor feeder monitoring.

14. Corresponding and changing operation in SMT placement machine production

(1) After production, select "finish" submenu to complete production;

(2) If other PCB, need to be produced, prepare for the change.

15. SMT power off and equipment cleaning completed

(1) Click RESET";

(2) Click the EXIT" icon;

(3) Turn off the main switch (rotating counterclockwise);

(4) Turn off the voltage stabilizer switch;

(5) Organize and clean the surrounding environment of the workplace.