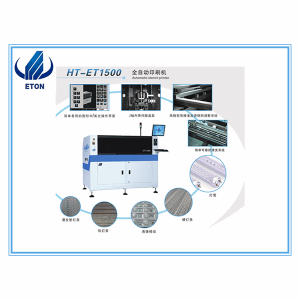

Automatic Solder Paste Stencil Printer

1.Technical Parameter:

|

HT-ET1500 Technical Parameter |

||

|

1 |

Scraper height | 65±1mm |

|

2 |

Scraper thickness | 0.25mm coating |

|

3 |

Printing mode | Single or double scraper printing |

|

4 |

Demoulding length | 0.02mm~12mm |

|

5 |

Printing speed | 0~200mm/s |

|

6 |

Printing pressure | 0.5~10KG |

|

7 |

Printing scope | ±765mm from the center |

|

8 |

Field of view | 10.24mm*6.4mm |

|

9 |

Platform adjustment range | Standard shape benchmark point(SMEMA standard),solder pad/openings |

|

10 |

Camera system | Independent camera,upwards/downwards imaging vision system,geometri matching location |

|

11 |

Repetition precision of image calibration | ±15 micron |

|

12 |

Repetition precision of printing | ±30 micron |

|

13 |

Cycle time | <15S,Cycle time/exclude printing&cleaning |

|

14 |

Power requirements | AC220V ±10% 50/60HZ,15A |

|

15 |

Compressed air requirements | 4~6kg/cm²,10.0 |

|

16 |

Operation System | Windows XP |

|

17 |

Environment temperature | 23±3℃ |

|

18 |

Relative humidity | 45~70%RH4 |

|

19 |

Product Changeover | <10 mins |

2.Features:

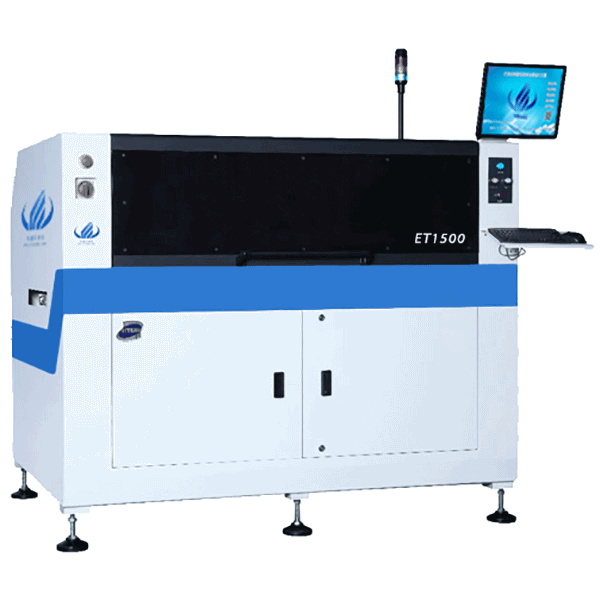

Eton automatic stencil printer HT-ET1500:

Apply to different kinds of PCB board,FR4,Aluminum,flexible PCB,FPCB etc.

Applicable PCB size: 1500mm length 500mm width.(Big size,more flexible)

Using windows XP operating system,indepent research and development of graphical man-machine interface.In particular,to do the program file navigation effect,to facilitate all operators quickly familiar with the operation;menu in Chinese/English switch,operation log,fault record/fault record/fault self-diagnosis/failure analysis tips/light alarm and other functions,making the operation simple and convenient.

Z axis screw servo direct connecting device,to ensure high precision,high speed and stripping stability.

With net frame rectifying and linear motor driving,the system is more stable than “platform correction system”,and therefore the machine is more in line with high precision requirement of printing.The stencil clamping system can be automatically positioned by stencil MARK point position data input without adapter,which is convenient for the flexible replacement of the stencil of different sizes.

High-power fan plus venturi vacuum generator device vacuum;dry,wet,vacuum three cleaning methods,and can choose any combination of free,the user can set the cleaning period,time,speed and other parameter according to actual needs;soft wear-resistant rubber wipe board,clean thoroughly,easy to disassemble.

3.Product Image:

4.Our service

- Help customer analyze product project and provide solution.

- Freely sample test.

- Skilled jig design services.

- Provide shipping/delivery information checking service.

- One year guarantee, all life maintain promise.

- 24 hours feedback speed by email of others.

Professional is our truth. Let's light up your business.